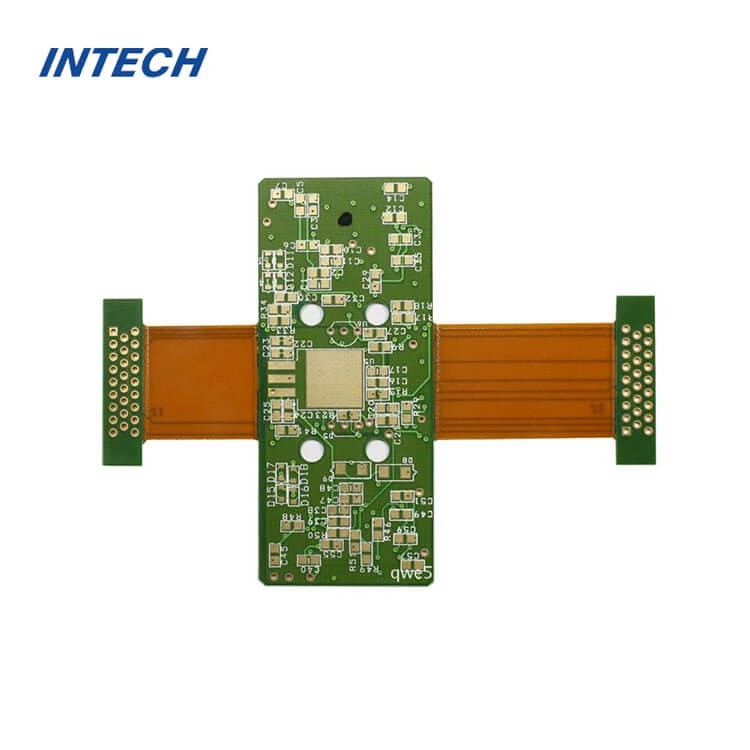

Technical points of PCB design and manufacture!

12/26/2024 As the core component of modern electronic equipment, the design and manufacturing technology of PCB directly determines the performance, stability and reliability of electronic products. This paper will deeply analyze the technical points of the design and manufacture of printed circuit boards to help readers better understand this process.Only by working together can we turn pcb assembly manufacturer The value of the play out, the development of the supply market needs. https://intechcircuit.com/

I. Key points of printed circuit board design

circuit design

Circuit design is the core of PCB design, which determines the function and performance of the circuit system. In circuit design, factors such as the layout of components, the direction of wires and the transmission of signals need to be considered to ensure the stability and reliability of the circuit system. At the same time, it is necessary to consider the size, number of layers and materials of the circuit board to meet the specific needs of the product.

Component selection

The choice of components has an important influence on the performance and stability of PCB. When selecting components, it is necessary to consider their performance parameters, packaging form, reliability and other factors to ensure that components can meet the requirements of the circuit system. At the same time, it is necessary to pay attention to the compatibility and replaceability of components, so that they can be replaced conveniently in the later maintenance and upgrade.

Thermal design

According to xiaobian of PCB factory, with the continuous improvement of power density of electronic equipment, thermal design becomes more and more important. In PCB design, it is necessary to fully consider the heat dissipation of components and adopt reasonable heat dissipation structure and materials to ensure that components can operate at normal working temperature.

Electromagnetic compatibility (EMC) design

Electromagnetic compatibility refers to the ability of electronic equipment to work normally in electromagnetic environment. In PCB design, it is necessary to consider factors such as electromagnetic radiation and electromagnetic interference, and adopt appropriate technical means such as shielding and filtering to ensure that electronic equipment can work normally in complex electromagnetic environment.

Second, the technical points of printed circuit board manufacturing

Material selection

When selecting materials, we need to consider its electrical properties, mechanical properties, heat resistance and other factors to ensure that PCB can meet the requirements of the circuit system. At the same time, we need to pay attention to the environmental protection and sustainability of materials to meet the green development requirements of modern manufacturing industry.

machining precision

The machining accuracy of PCB directly affects the stability and reliability of the circuit system. In the process of PCB manufacturing, it is necessary to adopt high-precision processing equipment and technology to ensure that the dimensional accuracy and wire accuracy of the circuit board meet the design requirements.

welding technique

Welding is one of the key steps in PCB manufacturing. Welding quality directly affects the performance and reliability of the circuit system. In the welding process, it is necessary to adopt appropriate welding methods and parameters to ensure the good connection between components and circuit boards. At the same time, we need to pay attention to the thermal stress and mechanical stress in the welding process to avoid damage to the circuit board.

Detection and testing

After the PCB is manufactured, strict inspection and testing are needed to ensure that the quality and performance of the PCB meet the design requirements. Testing and testing contents include electrical performance testing, mechanical performance testing, environmental adaptability testing, etc. Only through strict inspection and testing can we ensure the quality and reliability of PCB. The design and manufacturing technology of printed circuit board is a complex and delicate process, which needs to consider many factors comprehensively.

By deeply analyzing the technical points of its design and manufacture, we can better understand this process and provide a strong guarantee for the performance, stability and reliability of electronic products.